Well... When you see some club mate using their CNC machine, the only thing you can think about after that, is to have your own one ! That's done for me now !

The machine is ready for a while now, and it's time to do the presentation ! First thing, that look complicated, but after having a proper look, that's really easy ! The difficulties came from the supplies in Ireland.. Stuff you find everywhere else for cheap, cannot be found here or cost a fortune (yep... I was looking for a particular shredded bar...31 euros in France including p&p and accessories.. The same bar alone in Ireland : 141 euros !!!) Finally, I manage to build a CNC with materials I can find over here. That's why my machine is in steel, and not aluminium. Maybe that's a good thing for rigidity...

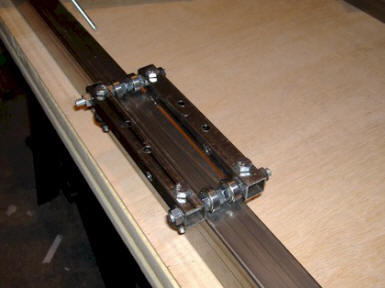

So, here we go ! The very first thing to make is a chassis and carriages. Carriages are made in 27x27 steel hollow bars, 8mm shredded bar and 608zz ball bearings. I used around 50 ball bearings for the entire machine.. I have around 50 left, if someone interested :o)

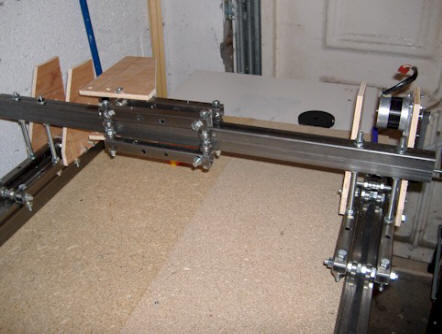

The rails are made with two 47x27 steel hollow bars, bolted together like an inverted "L" shape to have the biggest "runway" possible for the X axis carriages. By the way, the cnc machine is piloted by 3 stepper motors (1.1 Amp/round). The machine is built on the pulleys / belt system, which is really precise (around 0.01mm in theory). For more about this system, you can visit the great website from Guillaume Coquery, Father of the CNC machines for our use (in French).

Here are the only things you can't build yourself... you can find all that in the aeromaniacs website. The X axis is geared 18/32, such as the Y axis. The Z axis is geared 18/18.

One of the X axis carriage (move the machine forward / backward). Both are needed for a greater precision. Only 1 stepper motor drive both carriage, but the movement is fluid and precise.

You can see here the 2 X carriages and the Y carriage (move the machine left/right)

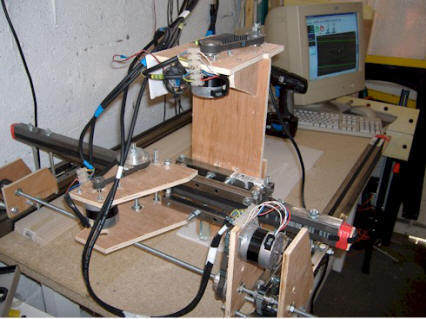

The stepper motor and the geared belt are mounted on wood structure. If you have the tools, you can use steel/aluminium and so on instead of wood, but that more than enough. The wood used here is 9mm plywood. Choose a very good quality here !

After that, the building is easy. It took me 2 week ends to build the mechanical part of the machine. I have no power tools to cut steel.. So, a bit of patience is needed here ! And don't hesitate to re-do a piece if that one is not correct ! To give you an idea, I used 6 mtrs of 47x27, 4 mtrs of 27x27 and around 5 mtrs of 8mm shredded bars. 100 8mm nuts and around 50 ball bearings...And 200 bird names !

So, finally, after all that, you have a completed machine ! Ready to receive the electronic. I use a CNC3AX card with a 12 volts power supply. For the stepper motors, I use three 19 volts/4.5 amps power supplies. You can go up to 36 volts if you need more power (the card can go to 40 volts), but 20 volts is more than enough. 12 volts will be for a "normal use".

On the software side, I use NINOS, but others software are widely available.

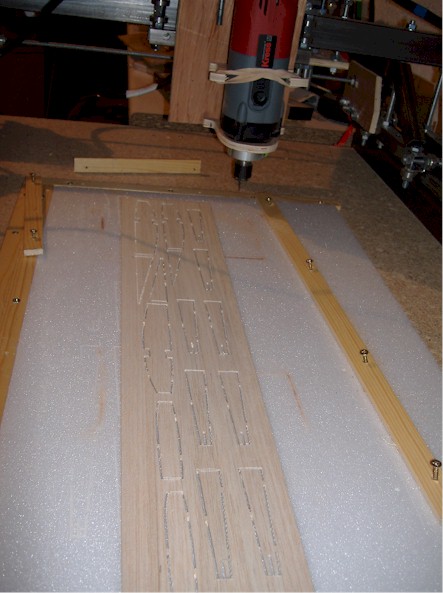

So, here is the machine :

As a router, I used a Dremel, but now, I'm using a Kress router... Since that, I saw the light ! I cut plywood like it's butter ! By the way, the machine speed can be up to 50mm/s, but in practice, I cut balsa at 30mm/s and plywood in one go at 10mm/s. What that mean ? Well, I can cut a sheet of balsa, full of ribs in less than 3 minutes... Yep... You can't go back after that !

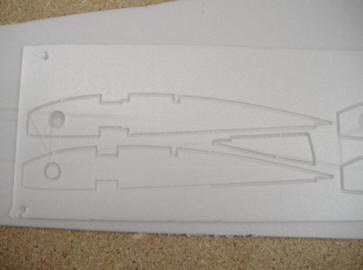

Some of my first test in Depron.. Some settings to be changed !

Much better now ! :o))

A video of one of the test can be found here (Right Click, save as...2Mo)

If you have any questions, contact me !