106

Radios / DIY Radio tray

« on: July 28, 2013, 10:17:20 AM »

Hi John,

just saw your post now. I used some left over tube I had and cut it in two. The lengths Fred mentioned sound about right, for some reason 180 mm comes to mind, but essentially it was half the length of the tube. The half lengths were close to TLAR in Freds original photos.

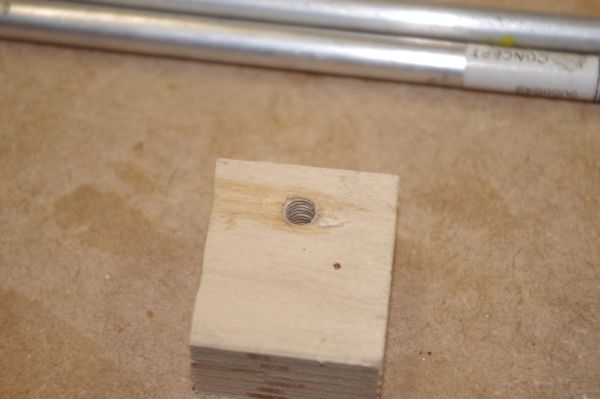

Not sure if I said earlier, but I used pins (actually lengths of paperclip) to lock my M6 nylon screws into the tubes. Can't remember if I used epoxy or cyano to hold them in place. Since my tube walls wre fairly thick l (1mm) I didn't think there would be much bending moment on the pins, so I could get away with a softer metal pin.

Stuff is all locked away to go travelling so can't measure at the moment.

Chris

just saw your post now. I used some left over tube I had and cut it in two. The lengths Fred mentioned sound about right, for some reason 180 mm comes to mind, but essentially it was half the length of the tube. The half lengths were close to TLAR in Freds original photos.

Not sure if I said earlier, but I used pins (actually lengths of paperclip) to lock my M6 nylon screws into the tubes. Can't remember if I used epoxy or cyano to hold them in place. Since my tube walls wre fairly thick l (1mm) I didn't think there would be much bending moment on the pins, so I could get away with a softer metal pin.

Stuff is all locked away to go travelling so can't measure at the moment.

Chris