Well, lack of wind and forecast snow showers meant no flying today :cry:

Instead I got my a**e in gear and cut the foam wings and fin for the Frogfoot. I'm currently using a drop arm cutter for wings and as the fin is highly tapered, I use a single point cutter for that.

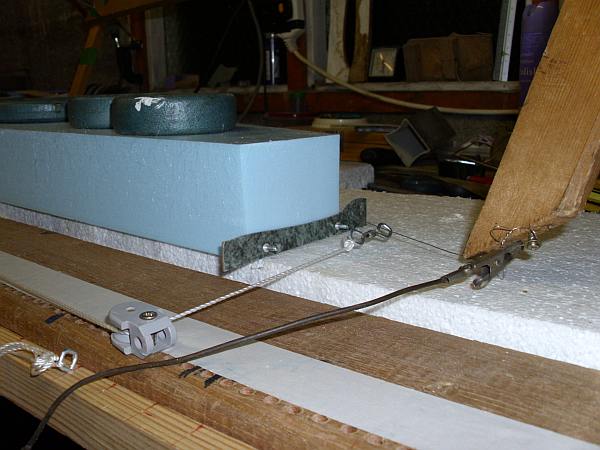

Using a drop arm cutter, you have an arm fixed at one end and by attaching the pull cords for the bow at different points, it pulls the ends of the bow through the foam at different speeds.

All set up and ready to go

Bottom template for the narrow chord at the tip

I'm waiting on a Hobby CNC kit coming from the US to complte my CNC cutter, which will make these cutters obsolete. They are useful for one off cuts and will satisfy the neds of most modellers