Yea, thanks for your suggestions lads. They both refer to over filling on top of the carbon tape and then re-sanding to return the wing to profile.

I guess what I am unsure about is just how critical is it to get the correct profile throughout the entire length of the wing. Remember each wing half is two meters long, and the profile changes. At the root it’s an SB96, and at the tip it’s an SB96V.

I’m thinking, okay, so I sand the groove too deep for the carbon tape. I glue the tape in place. When the glue had gone off I use filler to make up the difference, slightly over filling the remaining groove on top of the carbon tape so the filler stands proud above the original wing surface. When the filler has gone hard I start sanding. Here comes my point.

1/ The sanding block has a flat surface, the top of the wing is curved.

2/ if I just sand away the filler until I expose the foam sides of the top of the groove in the wing, then because the sanding block has a flat surface the top of the wing will now have a flat section running along the length of the top of the wing. (ie, the part of the wing above where I glued the carbon tape in.)

Because the top curvature of the wing is no longer there, (I sanded it away to make a groove to glue the tape into) I don’t know how much of a curve to sand the top of the groove to.

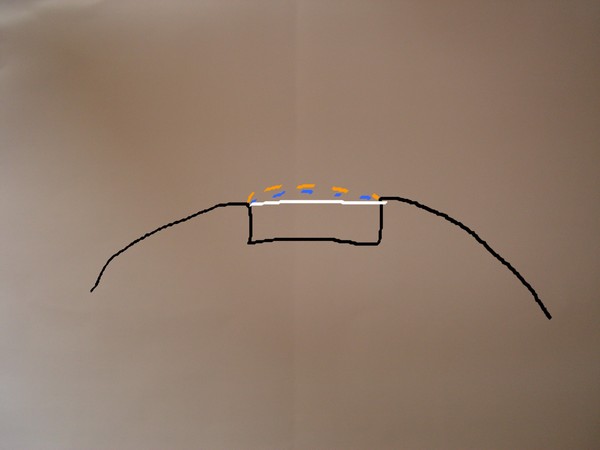

Have a look at the picture. (I’m not very good with “paint pot” I’m afraid.)

The picture is supposed to show the top of the wing profile.

Imagine I’ve sanded away a grove and fitted the tape and filler on top of it.

The white line shown the straight or ‘flat’ top that the sanding block would produce naturally.

Although exaggerated, the two coloured dotted lines show possible curvatures that I could shape the filler to, BUT… which curvature would be correct? (Having sanded the original curve away I no longer know what the correct curvature should be.)AND how do I sand it correctly for the entire length of the wing,…….and ensure that the other wing half is sanded to the same profile.

OR

Does it not really matter that much??? You see I have no idea how critical these profiles are.

Of course, what I don’t want to do is build the plane only to find it flys like a pig because the profile isn’t right!!!

I’m sure there is an answer to this matter, I just don’t know what it is, YET!

K.