So, after meeting with Little Keith, I have started modifying/repairing the wing before the plane even gets flown!

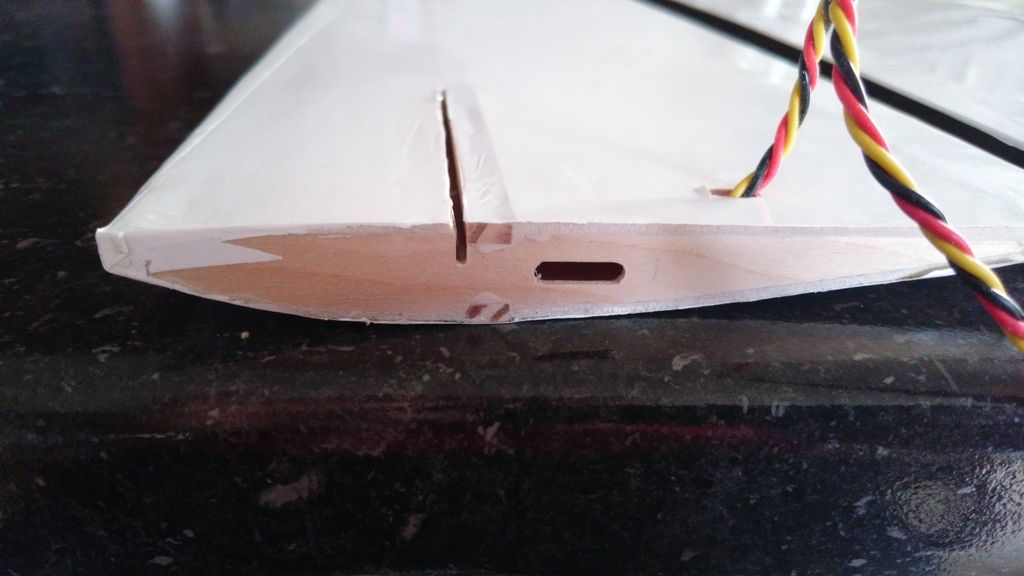

This is what I started with...

As you can see, the dihedral brace sits proud of the wing rib. That's what made me assume that the brace needed a cut-out on the underside of the wing.

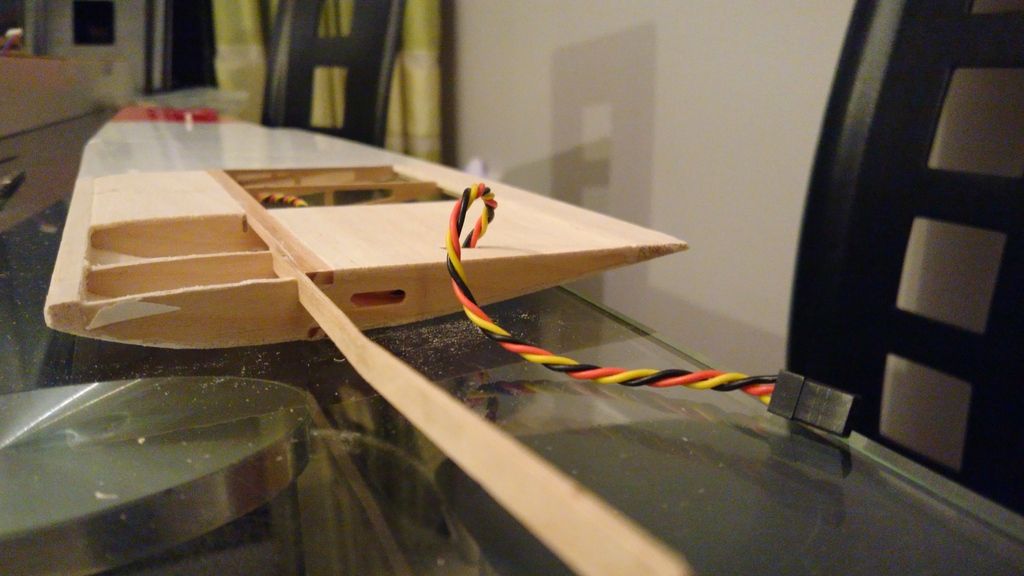

Unfortunately, doing that (making a cut-out) resulted in THIS...

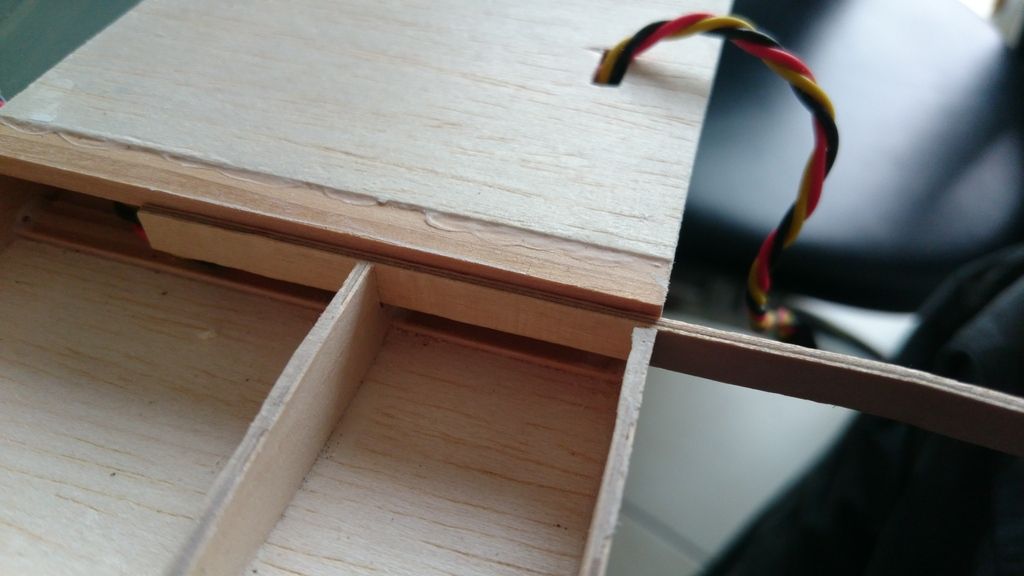

Getting busy with a junior hacksaw blade and a scrap of coarse sandpaper allowed me to deepen the notch in the ribs.

And a little bit of sawing and sanding gave me two light ply "mounts" to fit against Rib 3, two strips of light ply and balsa to recover the base of the wing and support the brace and two pieces to fit to Rib 3 to hold the brace (as it's too short to make it to Rib 3).

I think that was the easy bit... Actually gluing in the piece to hold the brace is going to be fiddly. L. Keith has also kindly donated a scrap of light ply from which I can fashion a replacement brace (for the inevitable hard landing).

After this, I still need to see about removing the covering from the tail plane to correctly create the bevel to allow deflection.

Maybe, just maybe, she'll be ready to fly for the spring! It's only taken approx 49 weeks so far!