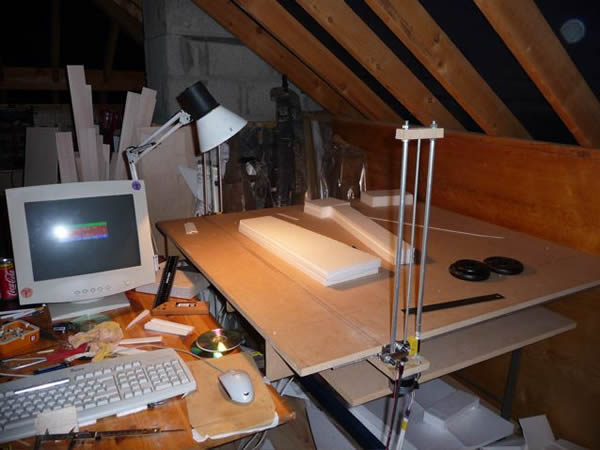

So here's my new baby

No elevator, no ailerons, no rudder. Ok so it doesn't even fly!!

For those interested (that's you Bill)

The table is the Super Spartia design. Build from MDF, Alu tubes, Alu angles, threaded rod, PCB and nuts and bolts.

The card is an Axemotion. They don't make it anymore I don't think. It was the cheapest one around at the time. I would have gotten the famous MM2001 card but I couldn't find one that was complete then, just kits.

The motors are Sanyo Denky.

Software is GMFC

All in it probably cost a little over €200. The cards a bit more these days. I bought mine a few years ago.

I have to say a big thanks to Keith. Keith drilled the cut the MDF carriages and made the rails from the aluminium angles. I just had to assemble it all and wire everything up. Took three or four evenings to get everything working as it should and the same tweaking it. Well I'm still tweaking it really! A few setbacks along the way as usual but not too bad. Not a lot of info about my card which was the main issue.

Bill you asked me if it is worth the time and effort. Yes is the answer for me anyway. To never have to make another template is a wonderful thing and now if I want to cut a wing I set it up in the computer and know that what I will get is right. It makes a lot of designs easy to build. Wings, EPP models, Fuse parts for plugs and lost foam fuselages etc..

It's a very handy tool to have basically and hopefully one that will serve me well for many years.

If someone needs something cut and is not in a big rush than I am happy to do it. I have white foam, hopefully some blue stuff soon as well and am ordering EPP too.

Here one of the first wings I'm working on. It's a wing for the Wazeco. Different profile than the original just to see how it works out.

As you can see I've added a cut for the wing joiner, the servo lead and aileron hinge cutaway. They've now been covered in obechi. The ailerons were glassed on the inside to make them nice and stiff (easy Keith:?). Will add more photos soon.