So, the latest update...

I manufactured and fitted the nice additional bits as suggested by Little Keith...

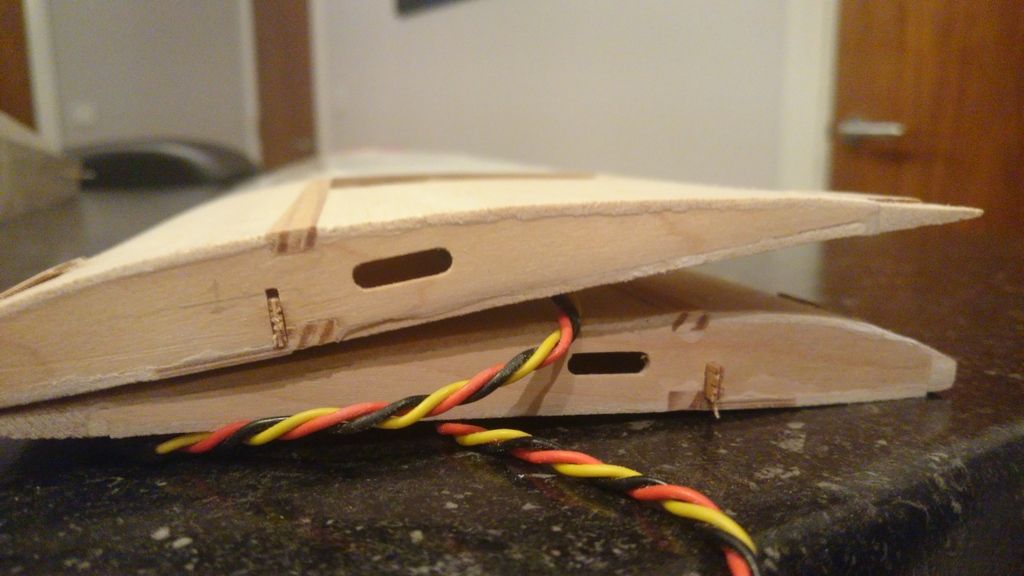

It all looks nice and clean and well repaired. Lets see how it all fits together...

The answer? It doesn't...

Ain't that just sweet!

A 1.5mm ply brace that snaps when you try and fit the elastics to the wing.

My question is: "what now?"

I have enough ply to remake one brace, but this is likely to happen again. I have 2 carbon rods from a previously crashed plane which could be used... My issue will be getting more 1.5mm balsa/ply to resurface the wing again.

If anyone is placing an order or can direct to anywhere in the SE that will have a little in stock, let me know.

Positives? It's all learning for No 2...