Hmmm, very good I must say!

So what subject are you studying Antonio? English language perhaps? You have very good descriptive skills.

After browsing through those build instructions for your Ninja I thought you might like to make use of this little tip. I use it for some of my models where the fuse and wings are retained by nylon screws.

To explain the purpose of this modification first:

I found that despite being an expert rc pilot, (okay,… so I tell lies,) there were some occasions, (

read, ‘often’) when the wind would suddenly change direction just as I was landing, or the ground would suffer a minor earth quake and momentarily rise up just as my plane was about to touch down. (Like I said,…I tell lies.) The net result of these totally unpredictable occurrences was that one wing tip would touch the ground before the fuse did. This resulted in a tremendous torque being applied to the wing / fuse area often resulting in damage to the afore mentioned parts of the airframe. :evil:

Having thought about this problem, I came to the following conclusion. That Force, being the Product of Inertia times Mass. Plus the fact that every action has an equal and opposite reaction, and that E = MCC and that I was getting more and more pissed off at having to repair repairs that themselves were repairs :evil: ,…I came up with this solution.

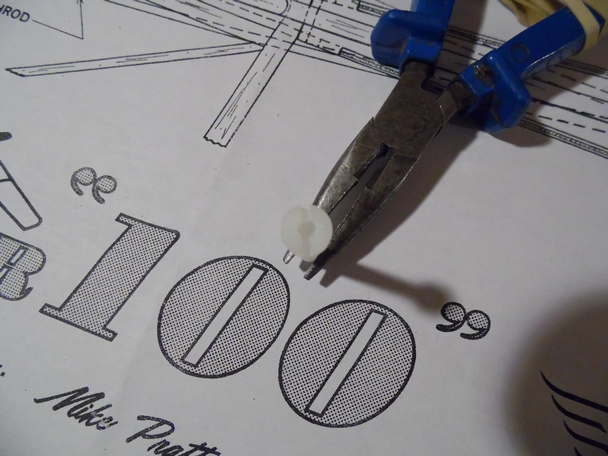

Drill a shallow hole through the head of the nylon retaining screws. By weakening the screw thus, the head of the screw ‘pops off’ when exposed to excess stress thereby allowing the wing to separate from the fuse and saving damage to either part of the airframe.

The only downside of this solution is the need for a constant supply of fresh nylon screws until such time as one gets better at landing. (That’s why I’m still drilling nylon screws! :oops: )

Here’s one I drilled earlier…….

Keep up the good work Antonio,...Tally-Ho.

Keith