1

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

2

Slope Soaring / Fpv gliding

« on: August 24, 2016, 17:18:05 PM »

I've made a self contained fpv camera system to fit on any glider or plane and am going to try it out on my trusty middle phase. To give myself some chance of success I have fitted the phase with a stabilisation system (switchable on or off). Center the sticks and it self rights and flies at a nice glide angle (I tested this on the slope and it works really well. It flies better than I can). I used a ccd board from a small quad using Libre pilot firmware. Now to try flying with goggles.

3

How to... / Cheap covering film

« on: June 08, 2016, 00:42:28 AM »

http://www.banggood.com/Heat-Shrinkable-Skin-5m-Yellow-Covering-Film-For-RC-Airplane-p-987903.html

Looking for cheap covering film? This stuff is great. As good as anything I've used, very opaque, 5m for less cost than 2m of usual stuff and free postage. If ordering get all rolls posted individually to avoid duty. Only downside is colour variability as I ordered the yellow as shown but received cub yellow instead (not complaining as I prefer cub yellow).

John.

Looking for cheap covering film? This stuff is great. As good as anything I've used, very opaque, 5m for less cost than 2m of usual stuff and free postage. If ordering get all rolls posted individually to avoid duty. Only downside is colour variability as I ordered the yellow as shown but received cub yellow instead (not complaining as I prefer cub yellow).

John.

4

Slope Soaring / Mini Fox

« on: February 27, 2016, 00:23:12 AM »

Fox chuck glider 22" span, covering with tissue and pu varnish. Using mini helicopter servos, gyro and receiver for control of ailerons and rudder. Looks like it will fit together.

5

Slope Soaring / Yet Another

« on: December 03, 2015, 22:59:20 PM »

Hi all,

A new one added to the stable. Quite a bit of sanding required with this kit, especially the ply. Upgraded the hinges and plastic links. This one's for the brother.

John.

A new one added to the stable. Quite a bit of sanding required with this kit, especially the ply. Upgraded the hinges and plastic links. This one's for the brother.

John.

6

Hi all,

I have flashed my turnigy 9x with the er9x firmware and all I can say is WOW! what a superb transformation. Anything is possible. Mind you it took a while to get familiar with the system. Programmes for models can be perfected on screen tested on a simulator and then downloaded into the transmitter. It supports telemetry, voice, everything I can think of. It's worthwhile spending the time to learn. It transforms a 100euro transmitter into a state of the art machine. Credit to the designer and even better letting us have it for free.

John.

I have flashed my turnigy 9x with the er9x firmware and all I can say is WOW! what a superb transformation. Anything is possible. Mind you it took a while to get familiar with the system. Programmes for models can be perfected on screen tested on a simulator and then downloaded into the transmitter. It supports telemetry, voice, everything I can think of. It's worthwhile spending the time to learn. It transforms a 100euro transmitter into a state of the art machine. Credit to the designer and even better letting us have it for free.

John.

7

Slope Soaring / Mini Quark build

« on: April 27, 2015, 00:42:28 AM »

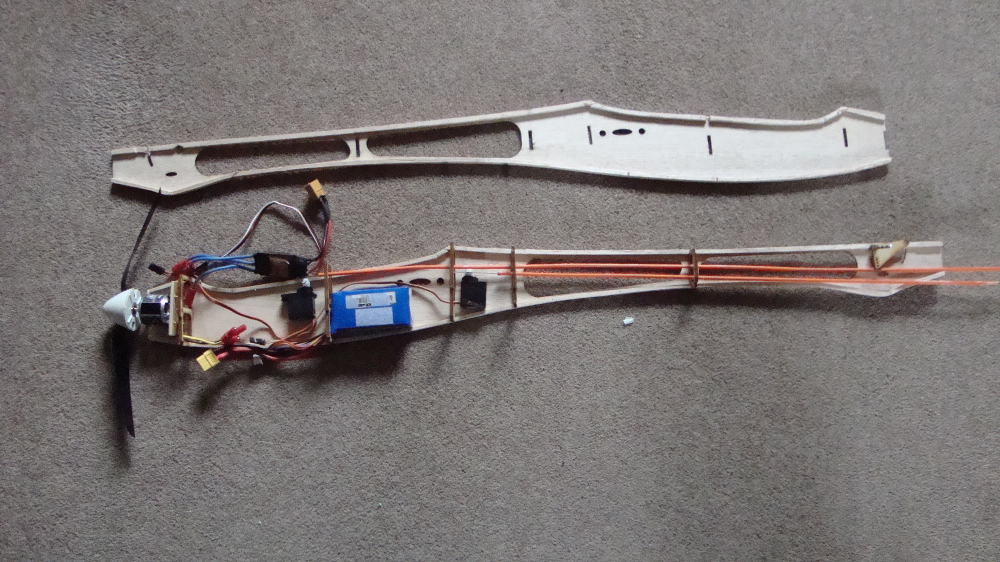

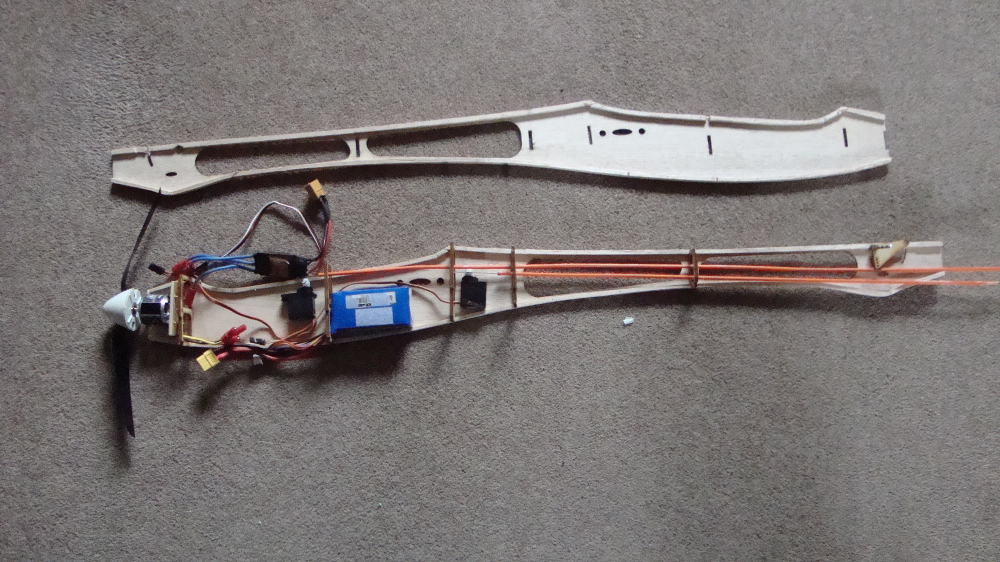

Hi all,

I received my quark mini kit last Friday, many thanks Fred, and as usual got stuck in straight away. The kit contains a detailed plan and all the wood needed for completion, beautifully cut and of good quality. The carbon spars, leading edges, wing joiners and control fittings must be purchased elsewhere.

I have decided to try an electric conversion using a Turnigy Park 450 1050kv motor with a 25 amp speed controller a 1200ma 3s zippy lipo and a 9xsomething folding prop. Servos are hobbyking 939 metal gear(never had one fail crashed and all) I have used this setup before on a glider with good results. The problem is fitting it all into this narrow fuse. I am using the layout as shown in the pic above doing away with the servo trays as supplied and gluing the servos to the fuse side. I will make a door on the underside for battery removal. I think with the layout as above the C/G will work out (time will tell).

So the build is started. I noticed the fuse slot for former C4 was not cut so I measured it up and cut it by hand on both sides. Servo mount ST1 needed corners filed to fit in formers C3 & C2 (I decided not to use it as gear wont fit), servo holes must be filed to suit servos used. Next the small bellcrank bushes are glued, one to each fuse side inners and aligned by putting fuse sides back to back and inserting a 3mm rod through the holes. The stripwood supplied can then be glued to the fuse edges (pins and a few cuts required), again when dry back up the fuse sides and sand flush with the laser cut black edges.

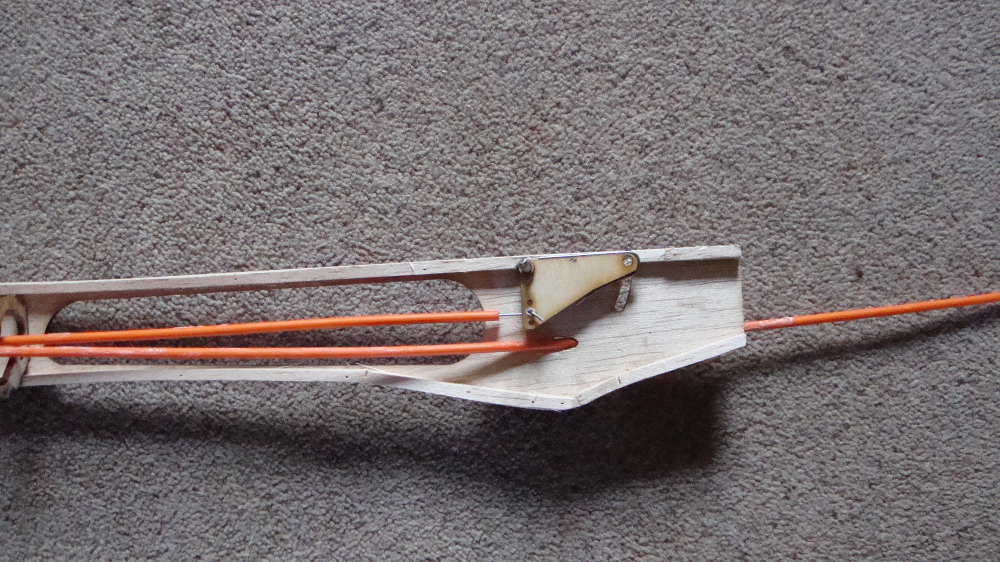

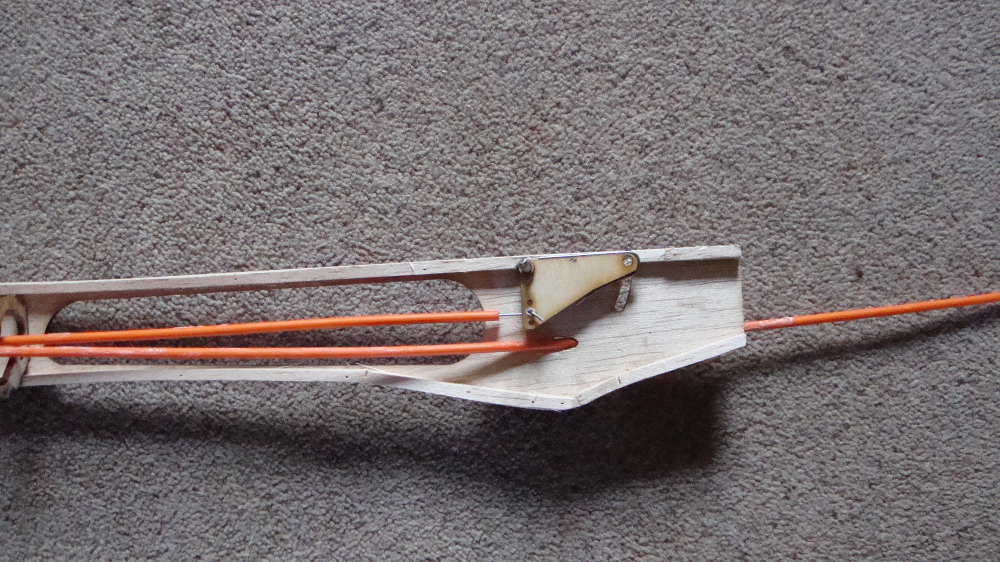

Glue the servos to the fuse sides or if using servo mounts assemble formers C3 and C4 and mount servos. I used snakes for the elevator and rudder controls and set up the bellcrank before joining the fuse halves (it's much easier this way). Glue a plywood shim to each side of the bellcrank alligning with a 3mm rod (a drill bit in my case), I bushed the bellcrank with a nylon tube to suit the snake wire (no play here is good), glued the servo to the fuse side, set it to neutral and made up the snake to give near neutral bellcrank as in the pic above(it's a little up but will trim out). Rudder snake is easy with a little filing of the fuse hole.

I then put the whole fuse together with the formers fitted but unglued, pin through bellcrank and taped everything into allignment and when happy ran cyano into each joint. I made a new front former slightly larger to suit the motor mount and fixed it approx 15mm rearward of the position of the C1 former. Getting started now on the motor cowling.

John.

I received my quark mini kit last Friday, many thanks Fred, and as usual got stuck in straight away. The kit contains a detailed plan and all the wood needed for completion, beautifully cut and of good quality. The carbon spars, leading edges, wing joiners and control fittings must be purchased elsewhere.

I have decided to try an electric conversion using a Turnigy Park 450 1050kv motor with a 25 amp speed controller a 1200ma 3s zippy lipo and a 9xsomething folding prop. Servos are hobbyking 939 metal gear(never had one fail crashed and all) I have used this setup before on a glider with good results. The problem is fitting it all into this narrow fuse. I am using the layout as shown in the pic above doing away with the servo trays as supplied and gluing the servos to the fuse side. I will make a door on the underside for battery removal. I think with the layout as above the C/G will work out (time will tell).

So the build is started. I noticed the fuse slot for former C4 was not cut so I measured it up and cut it by hand on both sides. Servo mount ST1 needed corners filed to fit in formers C3 & C2 (I decided not to use it as gear wont fit), servo holes must be filed to suit servos used. Next the small bellcrank bushes are glued, one to each fuse side inners and aligned by putting fuse sides back to back and inserting a 3mm rod through the holes. The stripwood supplied can then be glued to the fuse edges (pins and a few cuts required), again when dry back up the fuse sides and sand flush with the laser cut black edges.

Glue the servos to the fuse sides or if using servo mounts assemble formers C3 and C4 and mount servos. I used snakes for the elevator and rudder controls and set up the bellcrank before joining the fuse halves (it's much easier this way). Glue a plywood shim to each side of the bellcrank alligning with a 3mm rod (a drill bit in my case), I bushed the bellcrank with a nylon tube to suit the snake wire (no play here is good), glued the servo to the fuse side, set it to neutral and made up the snake to give near neutral bellcrank as in the pic above(it's a little up but will trim out). Rudder snake is easy with a little filing of the fuse hole.

I then put the whole fuse together with the formers fitted but unglued, pin through bellcrank and taped everything into allignment and when happy ran cyano into each joint. I made a new front former slightly larger to suit the motor mount and fixed it approx 15mm rearward of the position of the C1 former. Getting started now on the motor cowling.

John.

8

Scale / Curtiss P40

« on: February 19, 2015, 23:56:17 PM »

Pic of my latest finished build from an old aeromodeller plan. 34" P40 powered by os10

9

Scale / Warbird fly in

« on: September 03, 2014, 00:19:02 AM »

Hi all,

Warbird fly in next Sunday 8/09/2014 Shankill model flying club beside sugarloaf mountain. No MACI card no fly.

John.

Warbird fly in next Sunday 8/09/2014 Shankill model flying club beside sugarloaf mountain. No MACI card no fly.

John.

10

Park Flyers / Foamies / Great small flier

« on: August 06, 2014, 22:34:02 PM »

Hi All,

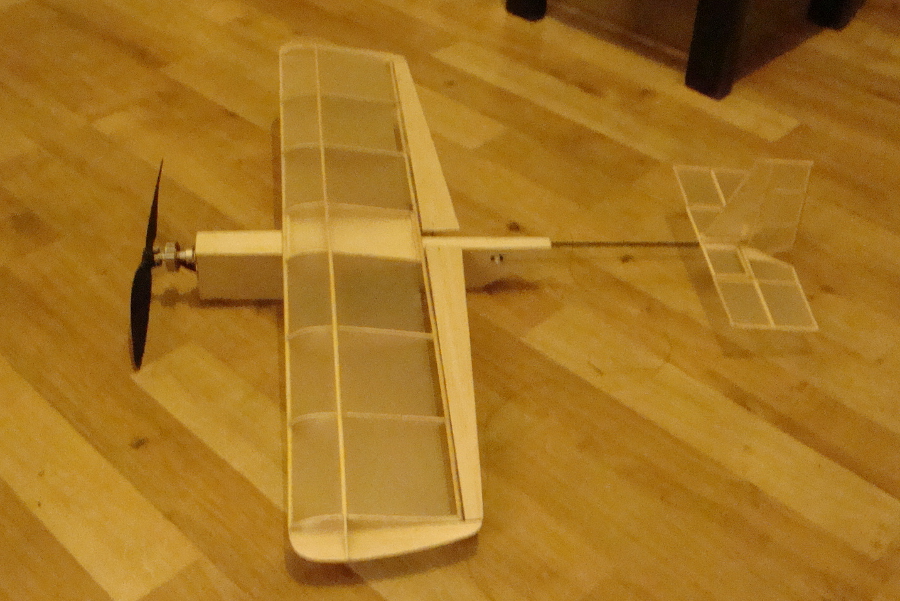

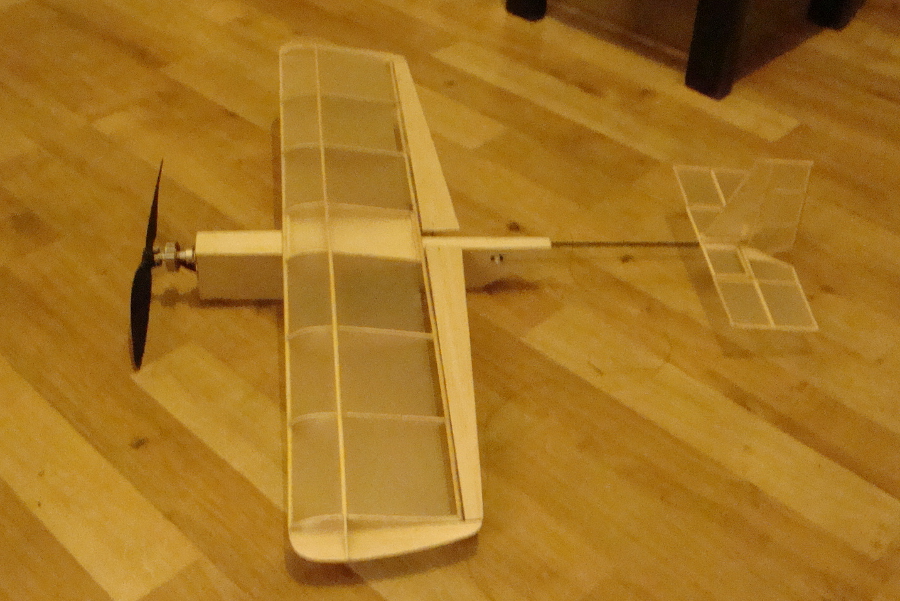

Here's a little model I made last week, constructed from 12" barbeque skewers for leading, trailing edges and spars , a few sheets of 1/16 balsa, a 3mm carbon rod. Wingspan is 25" and using 3 hobbyking 5 grm servos(aileron, elevator, rudder), hobbyking motor and 10 amp speed control.

It fits an 800mah 2s lipo in the fuse up front and is good for 10 mins+ flight time. Prop is an 8x6 inch attached using propsaver. The wing is symmetrical in section. Flying weight is 200g.

I have to say this is the best small model I have ever flown, even in strong wind it is easy to handle and very manouverable capable of walking speeds or zooming around. If anyone is interested in building one I would supply more details. It's a simple build as the built up tail feathers can be replaced with balsa sheet.

John.

Here's a little model I made last week, constructed from 12" barbeque skewers for leading, trailing edges and spars , a few sheets of 1/16 balsa, a 3mm carbon rod. Wingspan is 25" and using 3 hobbyking 5 grm servos(aileron, elevator, rudder), hobbyking motor and 10 amp speed control.

It fits an 800mah 2s lipo in the fuse up front and is good for 10 mins+ flight time. Prop is an 8x6 inch attached using propsaver. The wing is symmetrical in section. Flying weight is 200g.

I have to say this is the best small model I have ever flown, even in strong wind it is easy to handle and very manouverable capable of walking speeds or zooming around. If anyone is interested in building one I would supply more details. It's a simple build as the built up tail feathers can be replaced with balsa sheet.

John.

11

Plane for sale on done deal. Would make a nice Tug.

http://www.donedeal.ie/hobbies-for-sale/rc-plane-giant-1-4-scale-piper-cub/6827408

We could all chip in.

John.

http://www.donedeal.ie/hobbies-for-sale/rc-plane-giant-1-4-scale-piper-cub/6827408

We could all chip in.

John.

12

Scale / Jodel Bebe

« on: June 14, 2014, 00:04:49 AM »

Just completed my latest build from an old freeflight plan available on outerzone. Setup for rudder elevator and electric power. Hope to maiden this weekend.

John.

John.

13

Slope Soaring / Shankill Radio Club

« on: May 30, 2014, 22:13:39 PM »

Hi All,

Short notice I know. Shankill radio club (beside sugarloaf mountain) Fly in barbeque tomorrow Saturday from 11am. All welcome (MACI membership required to fly (no exceptions).

Sorry Fred put it here to be seen, you can delete tomorrow).

John.

Short notice I know. Shankill radio club (beside sugarloaf mountain) Fly in barbeque tomorrow Saturday from 11am. All welcome (MACI membership required to fly (no exceptions).

Sorry Fred put it here to be seen, you can delete tomorrow).

John.

14

Wanted / aerobat wanted

« on: November 05, 2013, 22:44:05 PM »

Hi all,

Anyone got a good ready made aerobat (not foamie) loitering in their collection that they might part with for the right price?

John.

Anyone got a good ready made aerobat (not foamie) loitering in their collection that they might part with for the right price?

John.

15

Slope Soaring / Quark tubes

« on: September 26, 2013, 22:44:22 PM »

Hi all,

I know this is off topic and posted in the wrong place but seeing as the fly in is this weekend I thought it might get more notice. Wondering has anyone any suitable tubing be it ally or carbon for my quark 2m. I need 10mm tube with a wing joiner rod to fit inside tubing and some 4mm tube into which fits a 3mm rod.

Thanks,

John.

I know this is off topic and posted in the wrong place but seeing as the fly in is this weekend I thought it might get more notice. Wondering has anyone any suitable tubing be it ally or carbon for my quark 2m. I need 10mm tube with a wing joiner rod to fit inside tubing and some 4mm tube into which fits a 3mm rod.

Thanks,

John.